Lucciano Pascucci of Oxford Township is the owner of a 3D design and printing business, creating various design solutions for home and business. In the following article, Lucciano Pascucci discusses how 3D printing is changing the automotive industry. In each of these changes we’ll see how 3D printing is being applied at nearly every stage of developing the vehicles themselves and get an idea of the future of automotive and 3D printing together.

As technology takes off and reaches new levels of momentum, so, too, do our vehicles! However, it is not only the engineering and speed capabilities that grow, but the changes because of innovations such as 3D Printing.

According to industry experts, the automotive industry is experiencing big changes as a result of the advent of 3D printing. Some of these include foundational technology that helps to build the cars, such as printed dies and molds, and some go even further back in the design process to create 3D prints of concept art.

Revolutionizing the Automotive Industry with 3D Design

Lucciano Pascucci says that because technology often moves so quickly, it can be difficult to keep track of the way that the advancements are effecting any industry. With automotive industries and their many branches and applications, this can be an even more overwhelming task!

In order to make it slightly less daunting and appreciate where 3D printing is taking the industry, Lucciano Pascucci narrowed it down. Below is a list at the top 3 ways 3D is changing the future of automotive technology:

- Design Concepts

- Building Tools

- 3D Printed Machinery

Lucciano Pascucci takes an even closer look at of these aspects to create quality efficiency, from bringing designs to life to aiding in the creation of machinery to creating that machinery on its own.

Design Concepts

One of the most exciting advancements of the 3D printed revolutions is found in the very early stages of designing a vehicle. Creating a car, as those in the know may already be aware of, does not start with machine parts, reports Lucciano Pascucci.

Instead, it generally begins with two-dimensional drawings and other artwork pieces that help those with the ideas to create a visual to work with. Many design companies take those very same drawings and create 3D models using modeling software.

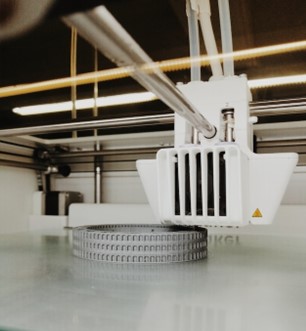

Those 3D models are then printed. Lucciano Pascucci explains that they streamline the whole process of taking a vehicle from an idea in someone’s head to a tangible machine. This also attracts business for customers of design studios because they see the various applications that a 3-dimensional design produced in short amounts of time can supply.

Building Tools

Not only does all of this go into the creation of a vehicle during the design phase, but each individual part and the tools used to create them are also treated to an involved process.

In fact, Lucciano Pascucci of Oxford Township says that leather molding is one of the factors that is time consuming for those involved in creating the trim for luxury cars. However, shaping and embossing leather has never been easier with the advent of tools created by 3D printing.

One company known as Makra Pro has created a die, distributing equal pressure across stretched leather, through 3D printing! This is just one example of the many tools being created to aid every step in the process.

3D Printed Machinery

3D Printed Machinery

Finally, Lucciano Pascucci of Oxford Township reports that the actual components of the car itself can be created using this technology, and already are! In fact, one of the most impressive examples of this is in the creation of spare engine parts for motorcycles.

That’s right; using 3D scanning and modeling software, it is possible to scan a real engine and simply print parts to fit and operate within that engine on a motorcycle. This opens the doors for future automotive industries to begin constructing vehicles entirely out of 3-dementially printed components.

In Conclusion

Lucciano Pascucci of Oxford Township notes that 3D printing is quickly becoming the new fact of manufacturing automotive. It is changing the industry in revolutionary ways, but perhaps the best way to describe these changes, overall, is in the word: efficiency.

With 3D prints not only of the concept art that goes into visualizing new car designs, but dimensional design elements like molds and even some of the lightweight parts themselves, there is no denying that this technology is invading every area of the automotive industry. With innovation, creating and using vehicles will be more efficient than ever before.